المنتجات الساخنة

Ceramic Balls SKF

网页2023年6月14日 Ceramic balls are available in many compositions and formulations. Ceramic balls resist corrosion and abrasion very well—features that make ceramic balls

Contact

Ceramic Bearings Emerson Bearing

网页2018年12月4日 Ceramic Bearings. Ceramic bearings are comprised of ceramic rolling elements (balls) enclosed in a ferrous (typically steel) inner and outer race. Since these

Contact

Hybrid ceramic ball bearings SKF

网页2023年5月31日 MRC Hybrid ceramic ball bearings use a combination of traditional 52100 steel rings precision matched with silicon nitride (ceramic) balls. In addition to being

Contact

Full article: Grease Performance in Ball and Roller Bearings

网页2023年3月21日 With different lubrication mechanisms in roller and ball bearings, it can also be expected that the difference in performance between roller and ball bearings will also

Contact

(PDF) On the Use of Ball Milling for the

网页2015年4月22日 In the present research work the mixture of boron carbide and graphite ceramic powders with a theoretical composition of 50%

Contact

Ceramic Ball Mill For Grinding Materials FTM

网页2022年9月5日 The ceramic ball mill is a small ball mill mainly used for mixing and grinding material. In ball mill ceramic industry, it has two kinds of grinding ceramic ball mill, one is dry grinding ceramic ball mill, and

Contact

Ceramic Ball Mill For Sale Automatic Ceramic Ball Mill

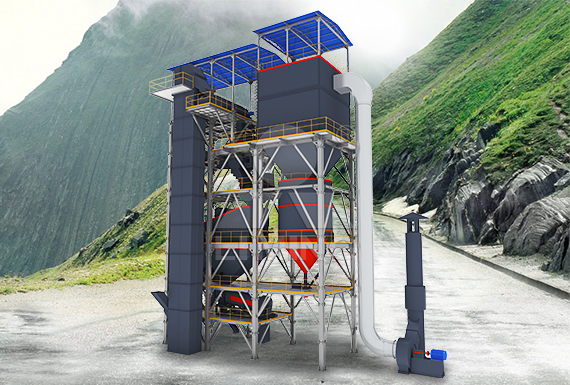

网页CERAMIC BALL MILL STRUCTURE. The ceramic ball mill is a horizontal cylinder ball mill. It is composed of the feeding part, discharging part, rotary part, transmission part (reducer,

Contact

Ceramic Ball Bearings Lily Bearing

网页Ceramic Balls. LILY Bearing provide a wide range of ceramic ball options across a variety of sizes. Material options include Silicon nitride (Si3N4), Zirconia (ZRO2), Alumina (Al2O3)

Contact

Dry Ball Mill/Ceramic Ball Bearing /Ball Bearings/Bearings

网页The dry grinding ball mill is a horizontal cylindrical rotating device, which is driven by outer gear. It is divided into lattice type dry ball mill and multi-bin type dry ball mill. The material

Contact

ceramic ball mill

网页2023年3月1日 Ceramic Ball Bearings. Benefits of Ceramic Ball Bearings Ceramic ball bearings [] 2023年3月1日.

Contact

Ceramic Balls SKF

网页2023年6月14日 Alumina Oxide Balls. Uses: Alumina Oxide ceramic balls may be used at temperatures up to 3180 ºF. Ceramic balls are extremely hard, resistant to abrasion, and immune to all furnace atmospheres. Applications where alumina oxide balls are used include chemical pumps, down-hole pumps, valves, bearings, gages, flowmeters, etc.

Contact

Characteristics and mechanism of surface damage of

网页2022年12月1日 In recent years, Si 3 N 4 hybrid ceramic ball bearings, which are representative of hybrid ceramic ball bearings, have been gradually applied and popularised in the high-speed spindles of precision machine tools [3]. Their main advantage is the low density of ceramics, being 40 % below that of steel, which reduces the centrifugal loading

Contact

Fabrication and service of all-ceramic ball bearings for

网页2021年1月1日 Fabrication and service of all-ceramic ball bearings for extreme conditions applications. S Li 1, C Wei 1 and Y Wang 1. Published under licence by IOP Publishing Ltd IOP Conference Series: Materials Science and Engineering, Volume 1009, The 5th International Conference on Computing and Solutions in Manufacturing Engineering

Contact

SKF

网页2023年6月29日 Gothenburg, 29 June 2023: SKF and Sinoma Nitride, an industry-leading developer and producer of silicon nitride materials and ceramic balls, have entered into a Joint Venture (JV) contract to deepen their cooperation within hybrid ceramic ball bearings. The cooperation is of strategic importance as ceramic bearings is a prioritized emerging

Contact

Research on Optimal Design and Processing of High

网页Thermal Characteristics Analysis of Mill Head of Five-Axis CNC Mill Machine Based on Finite Element Method Songhua Li. 2009. An full ceramic ball bearing without inner ring of hot isostatic pressing silicon nitride and its manufacturing method: China, ZL200610134118. 9.

Contact

Ceramic Ball Mill For Grinding Materials FTM

网页2022年9月5日 The ceramic ball mill is a small ball mill mainly used for mixing and grinding material. In ball mill ceramic industry, it has two kinds of grinding ceramic ball mill, one is dry grinding ceramic ball mill, and

Contact

Ceramic Ball Mill In Ecologic Use Fote Machinery

网页2023年6月25日 Fote Company upgrades the ceramic ball mills in many aspects 1 Dry grinding and wet grinding give people more choice when process materials with different properties.; 2 The motor of the ceramic ball mill is started by the coupling reduce voltage which can lower the starting electricity, and the ball mill's structure is divided into integral

Contact

Ceramic Ball Mill For Sale Automatic Ceramic Ball Mill

网页Free Maintenance Ceramic Ball Mill Grinding Process CERAMIC BALL MILL STRUCTURE The ceramic ball mill is a horizontal cylinder ball mill. It is composed of the feeding part, discharging part, rotary part, transmission part (reducer, transmission gear, motor, and electrical control device), lining plate, grinding medium, and other components.

Contact

Ceramic ball mill-BAILING® Machinery

网页2019年1月21日 Ceramic ball mill . Cylinder speed:14-36r/min Weight:3-18.6t Motor power:5.5-90kw Ceramic ball mill is mainly used for mixing, grinding process. It can be used both in dry grinding process and wet process. Bearing adopts oil lubrication system, thus help bearing internal dirt cleaning and reduce the bearing attrition during normal

Contact

ceramic ball mill

网页2023年3月1日 Ceramic Ball Bearings. Benefits of Ceramic Ball Bearings Ceramic ball bearings [] 2023年3月1日.

Contact

Ceramic Balls SKF

网页2023年6月14日 Alumina Oxide Balls. Uses: Alumina Oxide ceramic balls may be used at temperatures up to 3180 ºF. Ceramic balls are extremely hard, resistant to abrasion, and immune to all furnace atmospheres. Applications where alumina oxide balls are used include chemical pumps, down-hole pumps, valves, bearings, gages, flowmeters, etc.

Contact

Characteristics and mechanism of surface damage of

网页2022年12月1日 Jianqiu Wang a c,En-Hou Han a Add to Mendeley https://doi/10.1016/j.engfailanal.2022.106784 Get rights and content Keywords Precision hybrid bearing Ceramic ball Performance degradation Surface deformation layer Rolling contact fatigue (RCF) 1. Introduction

Contact

Super-precision bearings SKF

网页2023年5月31日 Angular contact ball bearings Available in a wide selection of designs and materials including four ISO dimension series in numerous executions these bearings can be incorporated into virtually every application where precision bearings are required. View more Cylindrical roller bearings

Contact

Fabrication and service of all-ceramic ball bearings for

网页2021年1月1日 Fabrication and service of all-ceramic ball bearings for extreme conditions applications. S Li 1, C Wei 1 and Y Wang 1. Published under licence by IOP Publishing Ltd IOP Conference Series: Materials Science and Engineering, Volume 1009, The 5th International Conference on Computing and Solutions in Manufacturing Engineering

Contact

SKF

网页2023年6月29日 Gothenburg, 29 June 2023: SKF and Sinoma Nitride, an industry-leading developer and producer of silicon nitride materials and ceramic balls, have entered into a Joint Venture (JV) contract to deepen their cooperation within hybrid ceramic ball bearings. The cooperation is of strategic importance as ceramic bearings is a prioritized emerging

Contact

Thermal Dynamic Exploration of Full-Ceramic

网页2022年9月6日 A silicon nitride ceramic bearing has good self-lubricating characteristics. It still has a good operational status under the condition of a lack of oil. However, the temperature distribution of a silicon nitride

Contact

Research on Optimal Design and Processing of High

网页Thermal Characteristics Analysis of Mill Head of Five-Axis CNC Mill Machine Based on Finite Element Method Songhua Li. 2009. An full ceramic ball bearing without inner ring of hot isostatic pressing silicon nitride and its manufacturing method: China, ZL200610134118. 9.

Contact

Ceramic Ball Mill For Sale Automatic Ceramic Ball Mill

网页Free Maintenance Ceramic Ball Mill Grinding Process CERAMIC BALL MILL STRUCTURE The ceramic ball mill is a horizontal cylinder ball mill. It is composed of the feeding part, discharging part, rotary part, transmission part (reducer, transmission gear, motor, and electrical control device), lining plate, grinding medium, and other components.

Contact

Ceramic ball mill-BAILING® Machinery

网页2019年1月21日 Ceramic ball mill . Cylinder speed:14-36r/min Weight:3-18.6t Motor power:5.5-90kw Ceramic ball mill is mainly used for mixing, grinding process. It can be used both in dry grinding process and wet process. Bearing adopts oil lubrication system, thus help bearing internal dirt cleaning and reduce the bearing attrition during normal

Contact

Ceramic Ball Mill In Ecologic Use Fote Machinery

网页2023年6月25日 Ceramic Ball Mill Ball mill is the key equipment for grinding after crushing process. Applied materials: cement, silicate, new-type building material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass, ceramics, etc. Model: 600×700 Power: 0.05 kw Capacity: 0.05 t/time Small-sized Medium-sized Large-sized

Contact